Industrial Equipment

UTE Trays: Benefits and Disadvantages of Steel vs Aluminium

If you need to increase your UTE’s cargo-carrying capacity, then you’re probably looking at all the different UTE trays available today. Most UTEs arrive with a standard tub unless you pick the factory tray option. If you’re already exploring the options on the market, you’ve probably noticed that most trays are made of either aluminium or steel.

While both types will do the job just fine, they have their own distinct advantages and disadvantages depending on the environment in which they’ll be used and the tasks they’re expected to perform. That being said, here are a few things to think about before you start shopping for UTE trays and suitable accessories for UTE trays.

source: caradvice.com.au

Weight Difference

Aluminium is about half the weight of steel. So, for instance, if a heavy-duty UTE tray made of aluminium weighs 150kg, you can expect its steel counterpart to weigh over 300kg. The negative effects of weight are mostly felt on fuel consumption, tyre and mechanical wear.

source: pediaa.com

However, you should also remember that the weight of the tray will also need to be considered in the vehicle’s kerb weight, which reduces its gross vehicle mass rating and consequently, its payload. In other words, the heavier the tray and accessories for UTE trays, the smaller the payload. This can be an especially important consideration when payload capacity is crucial.

But the extra weight of steel trays can also be beneficial, especially in cab-chassis vehicles that are driven unladen and with lighter loads. This is due to the fact that the leaf-spring rear suspensions of these vehicles are designed to carry over 1 tonne of payloads or more, so they can become stiff without sufficient load over them and end up punching your head through the roof every time you drive over a bump. A heavier steel tray will provide the sprung weight necessary to compress the rear springs enough to provide a comfortable, quality ride even when the tray is empty.

source: tleng.com.au

Strength

Generally, steel is almost three to four times stronger and stiffer than aluminium. So, if hardness and strength are essential for your application, steel trays are the obvious choice. However, that doesn’t mean that heavy-duty aluminium UTE trays don’t offer ample rigidity and strength. Most people with a quality aluminium tray are more than happy with their performance, even in harsh environments, so it all comes down to your specific work requirements.

Having said that, if your work involves carting around loads of heavy steel jackhammer drill bits, Acrow props, sledgehammers, star pickets, etc. that are typically thrown aboard instead than carefully placed, a steel tray will be better suited to handle that type of abuse. Steel can also prove to be the better choice if you’re carting landscape supplies such as hard jagged rocks that can tumble with a lot of force. But keep in mind that the extra weight of steel trays will reduce the amount of load you can carry.

source: bossbuilt.com.au

Corrosion Resistance

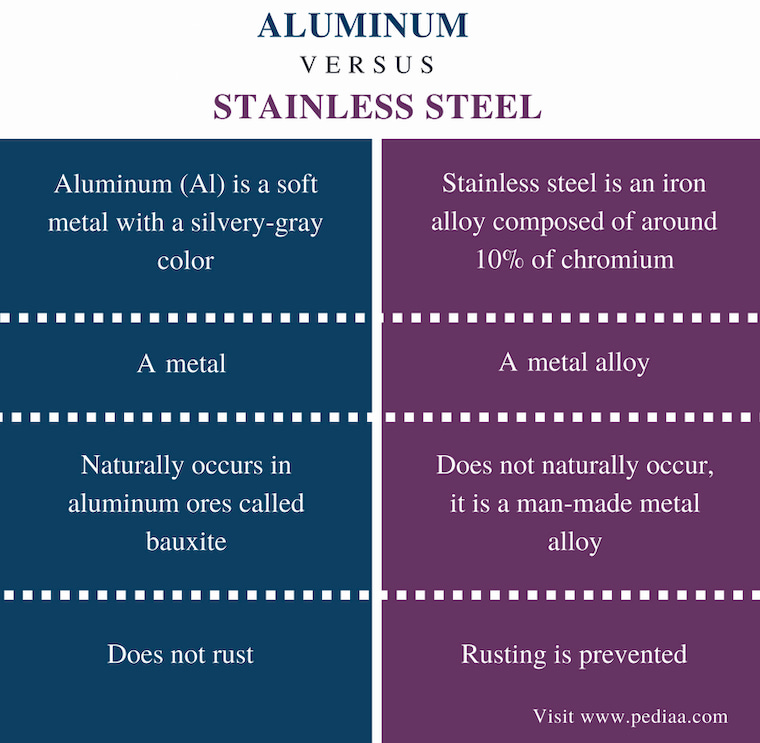

Besides being lighter, aluminium is also corrosion-resistant. Steel is made from alloys of carbon and iron, whereas aluminium is made from bauxite, making it rust-free and non-ferrous. That being said, you don’t need to provide any extra protection to aluminium trays from the elements, which is especially beneficial if you’re working or living in coastal environments where exposure to sea air and saltwater won’t result in rust.

Steel, on the other hand, needs to be sealed in some way to prevent rust, and saltwater is one of its biggest enemies. The best way to prevent rust on steel is by galvanising, powder-coating it or applying a decent lick of paint. Regardless of the treatment you go for, scratches and chips that are the result of hard use will always lurk around as potential rust starters. Luckily, the steel used for constructing is thicker than the sheet-metal used for manufacturing automotive bodies.

Cost

Aluminium is more expensive than steel, so you should expect an aluminium tray to cost more as a result. That’s typically the case with custom-made trays, as they’re made using more expensive raw materials, specialised TIG/MIG welding gases and labour as a result of the longer fabrication times.

source: gesrepair.com

However, the difference in price isn’t consistent across pre-fabricated tray products, which are generally the preferred option for many vehicle dealers. These trays are delivered in flat-pack kit form and are bolted as “drive away no more to pay package”. But in some cases, flat-pack trays cost more depending on shipping costs and design. And even though these trays aren’t tailored to suit a specific application like their custom-made counterparts, they’re almost half the price and are in many cases adequate for the tasks they’re expected to accomplish.

Conclusion

These are the key factors that you need to consider. If you still aren’t confident that you’ll make the right purchase, ask people in your line of work why they choose an aluminium or steel tray, whether it suits their requirements and what shortcomings they’ve noticed in the field. That’s the best way to make sure you get the right product on your first try.

Writing for the blog since 2012, Chris simply loves the idea of providing people with useful info on business, technology, vehicles, industry, sports and travel – all subjects of his interest. Even though he sounds like quite the butch, he’d watch a chick flick occasionally if it makes the wife happy, and he’s a fan of skincare routines though you’d never have him admit that unless you compliment his impeccable skin complexion.