Automotive

Untangling the Complexity: A Comprehensive Guide to Vehicle Wiring Harnesses

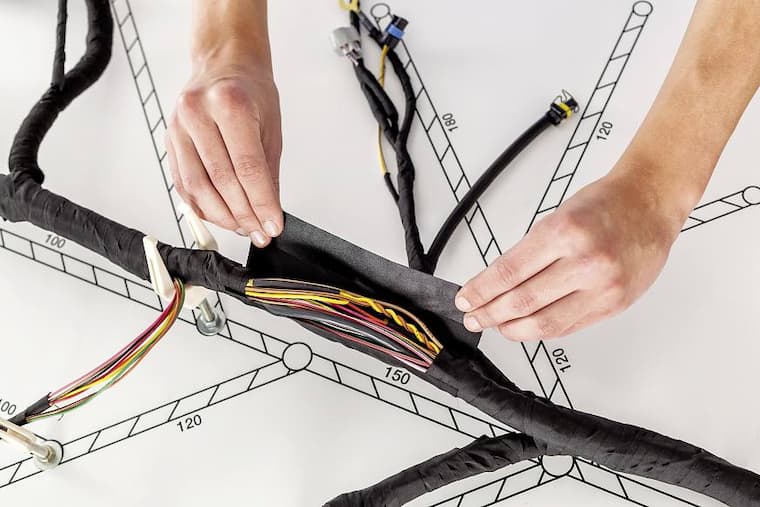

In the intricate web of automotive engineering, few components play a more crucial role than the vehicle wiring harness. Often hidden beneath the sleek exteriors and intricate interiors of modern cars, wiring harnesses serve as the nervous system, connecting and coordinating the various electrical components that power and control the vehicle. This comprehensive guide unravels the complexity of vehicle wiring harnesses, exploring their functions, types, construction, and the pivotal role they play in the seamless operation of today’s sophisticated automobiles.

I. The Heart of the System: Understanding Vehicle Wiring Harnesses

1. Definition and Purpose

A vehicle wiring harness, also known as a wiring loom or cable assembly, is a complex network of insulated wires, connectors, and terminals designed to transmit electrical signals and power between different components of a vehicle. Its primary purpose is to provide a reliable and organized conduit for electrical systems, ensuring seamless communication between various parts of the vehicle.

2. Functions of Wiring Harnesses

Wiring harnesses serve multifaceted functions within a vehicle, including the transmission of power, data, and control signals. Key functions include powering lighting systems, managing engine control units (ECUs), facilitating communication between sensors and actuators, and supporting entertainment and navigation systems.

II. Types of Vehicle Wiring Harnesses

1. Main Wiring Harness

– The main wiring harness serves as the backbone of the entire vehicle’s electrical system, connecting major components such as the engine, transmission, and main power distribution points. It is the central hub that facilitates communication between various subsystems.

2. Engine Wiring Harness

Focused on the engine compartment, the engine wiring harness connects the engine components, sensors, and actuators. It plays a critical role in ensuring precise control of the engine, managing fuel injection, ignition timing, and other crucial functions.

3. Chassis Wiring Harness

– The chassis wiring harness encompasses the wiring that runs through the vehicle’s chassis, connecting various components like lights, brakes, and the dashboard. It plays a crucial role in vehicle safety and functionality.

4. Body Wiring Harness

– Responsible for wiring within the vehicle’s body, this harness connects components such as power windows, door locks, interior lighting, and climate control systems. It ensures seamless communication between these features for a comfortable and user-friendly experience.

5. Instrument Panel Wiring Harness

– Specifically dedicated to the instrument cluster and dashboard components, the instrument panel wiring harness connects various gauges, indicators, and controls, providing the driver with essential information.

6. Door Wiring Harness

– Focused on the wiring needs of the doors, this harness connects components like power windows, locks, and speakers. It ensures reliable communication between the vehicle’s main system and these essential features.

III. Construction of Vehicle Wiring Harnesses:

1. Wires and Insulation

The core of a wiring harness is the multitude of wires it contains. These wires are typically made of copper due to its excellent conductivity. Each wire is insulated to prevent electrical interference and short circuits. The insulation material is often made of thermoplastics or thermosetting materials, providing durability and resistance to heat and chemicals.

2. Connectors and Terminals

Connectors and terminals act as junction points where wires come together. Connectors facilitate the easy installation and removal of components, while terminals ensure a secure electrical connection. These components are crucial for the modular and serviceable nature of modern vehicle wiring harnesses.

3. Tapes, Wraps, and Looms

To organize and protect the multitude of wires within a harness, automotive engineers use tapes, wraps, and looms. These materials not only bundle wires together neatly but also provide insulation against external factors like heat, moisture, and vibrations.

4. Protective Conduit

– In areas where wires are exposed to harsh conditions, such as the engine compartment, protective conduits are employed. These conduits shield the wires from physical damage, abrasion, and exposure to elements, ensuring the longevity and reliability of the wiring harness.

IV. The Evolution of Wiring Harness Technology:

1. Modular Design

Modern vehicles are designed with modular components, and wiring harnesses follow suit. Modular wiring harnesses enable easier assembly, repair, and replacement of specific sections, minimizing downtime during maintenance.

2. Smart Wiring Systems

With the advent of smart vehicles, wiring harnesses have evolved to accommodate sophisticated electronic systems. High-tech features like advanced driver assistance systems (ADAS), infotainment, and connectivity demand intelligent wiring solutions that can handle complex data transfer and communication.

3. Fiber Optic Integration

Fibre optic cables are increasingly integrated into wiring harnesses to transmit data at high speeds with minimal signal loss. This is particularly relevant in the context of in-vehicle communication systems and entertainment networks.

4. Electrification and Hybrid Vehicles

The rise of electrified and hybrid vehicles introduces new challenges for wiring harnesses. High-voltage wiring, battery management systems, and complex control logic require advanced harness designs to ensure safety and efficiency.

V. Challenges and Solutions in Wiring Harness Design

1. Weight and Space Constraints

As vehicles become more compact and lightweight, wiring harnesses face challenges in terms of weight and space constraints. Engineers address this by employing advanced materials, efficient designs, and precise routing.

2. Electromagnetic Interference (EMI)

The proliferation of electronic components in modern vehicles increases the risk of electromagnetic interference. Wiring harnesses incorporate shielding and grounding techniques to mitigate EMI and ensure the proper functioning of sensitive electronic systems.

3. Durability and Reliability

Vehicles operate in diverse and challenging conditions. Wiring harnesses must withstand heat, moisture, vibrations, and mechanical stress. Robust materials and thorough testing processes are employed to enhance durability and reliability.

VI. Future Trends in Vehicle Wiring Harnesses:

1. Integration with Autonomous Systems

The rise of autonomous vehicles will necessitate wiring harnesses capable of supporting complex sensor networks, communication systems, and control mechanisms required for safe and efficient autonomous operation.

2. Advanced Materials and Manufacturing Processes

Ongoing research focuses on developing lightweight yet durable materials and streamlined manufacturing processes to meet the evolving needs of modern vehicles.

3. Enhanced Diagnostic Capabilities

Future wiring harnesses may incorporate advanced diagnostic features, enabling real-time monitoring and quick identification of faults for efficient maintenance and repair.

VII. Conclusion: Navigating the Electrical Highway

In the intricate landscape of modern automobiles, the vehicle wiring harness stands as a testament to the intricate dance of technology and engineering. As vehicles continue to evolve with electrification, autonomy, and connectivity, the role of wiring harnesses becomes increasingly pivotal. From the simplicity of copper wires to the sophistication of fibre optics, wiring harnesses weave a tale of progress, innovation, and the quest for seamless connectivity. As we navigate the electrical highway of the automotive future, the vehicle wiring harness remains an unsung hero, ensuring that every electrical impulse flows with precision, contributing to the efficiency, safety, and intelligence of our beloved vehicles.

Writing for the blog since 2012, Chris simply loves the idea of providing people with useful info on business, technology, vehicles, industry, sports and travel – all subjects of his interest. Even though he sounds like quite the butch, he’d watch a chick flick occasionally if it makes the wife happy, and he’s a fan of skincare routines though you’d never have him admit that unless you compliment his impeccable skin complexion.