Industrial Equipment

Benefits of Ohmmeters and the Different Types

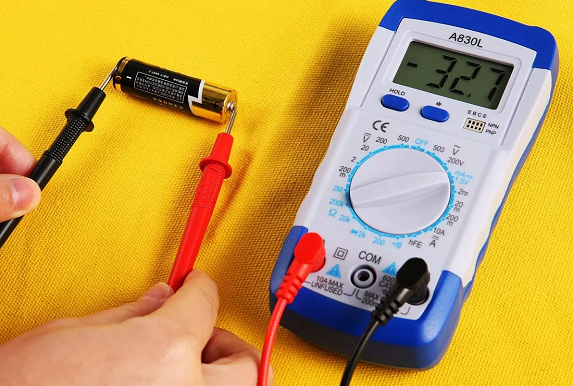

Ohmmeters, also known as low resistance meters, are important pieces of test equipment used to identify components where the resistance has surpassed acceptable values, which can lead to several undesirable outcomes. These can include energy loss, overheating, protective fault device malfunction, failure during power surges and poor grounding. The test results you get from the low resistance meter can identify changes caused by temperature, corrosion, fatigue, vibration and any other condition that can occur on the worksite.

A low resistance meter can be used in a wide range of industries and even DIY projects, but the industries with the most resistance problems are motor armature, transformer testing, UPS, circuit breakers, cable-reel, aircraft and automotive assembly, railroad industry, welding spot or seam and so on. There are a few different low resistance meter types you can pick from, namely: milli-ohmmeters, 10 A micro-ohmmeters, 100+ A micro-ohmmeters and transformer ohmmeters.

Milli-Ohmmeters

Milliohmetters are typically used for component and general circuit verification. They’re less sensitive and more affordable than micro-ohmmeters, which makes them the ideal choice if measurement resolution and sensitivity are not important. The maximum test current of these meters is usually less than 2A and as low as 0.2A.

10A Micro-Ohmmeters

10A micro-ohmmeters are the go-to choice for most operators as they cover the majority of field applications. They provide not only a suitable and comfortable test current throughout the entire test, but they’re also lightweight and have an improved battery operation. Some models have different measurement modes that address different types of testing conditions.

100+A Micro-Ohmmeters

Testing contact resistance of high-voltage circuit breakers requires a test current with a value between 50A and the rated normal current. Most electrical utilities should be tested as higher currents, as that’s more representative of their working conditions. The micro-ohmmeters that are used for this type of testing are able to deliver anywhere from 100A to 600A. Cables, cable joints, bus bars, and welds are all tested with the help of this type of micro-ohmmeters.

Transformer Ohmmeters

These ohmmeters are specifically designed for measuring tap changers and transformer windings. Some models include dual meters with independent range controls so that high resistance and low resistance windings can be measured at the same time. Additionally, these devices are multi-current devices and feature a measurement resolution to 1 micro-ohm, and they can be used for field operating verification, factory tests, performing heat runs to determine internal temperature changes and helping to locate defects in transformers, like for instance loose connections.

Writing for the blog since 2012, Chris simply loves the idea of providing people with useful info on business, technology, vehicles, industry, sports and travel – all subjects of his interest. Even though he sounds like quite the butch, he’d watch a chick flick occasionally if it makes the wife happy, and he’s a fan of skincare routines though you’d never have him admit that unless you compliment his impeccable skin complexion.