Automotive

The Complete Guide to Mass Air Flow Sensors (MAF)

The massive power and torque numbers that we see in today’s cars are owed to the tech that’s been refined over the years, and none more so than electronic fuel injection. This marked a tectonic shift from carburetted engines. Engines not only found more power with the same displacement but also became more efficient and used less fuel. Behind the long list of advantages (better acceleration, fewer emissions, and improved starting among others), lies a computer-controlled network of sensors that all have the task to optimise air and fuel ratios under different driving conditions. A key component in this complex network is the mass air flow sensor.

What is a Mass Air Flow Sensor?

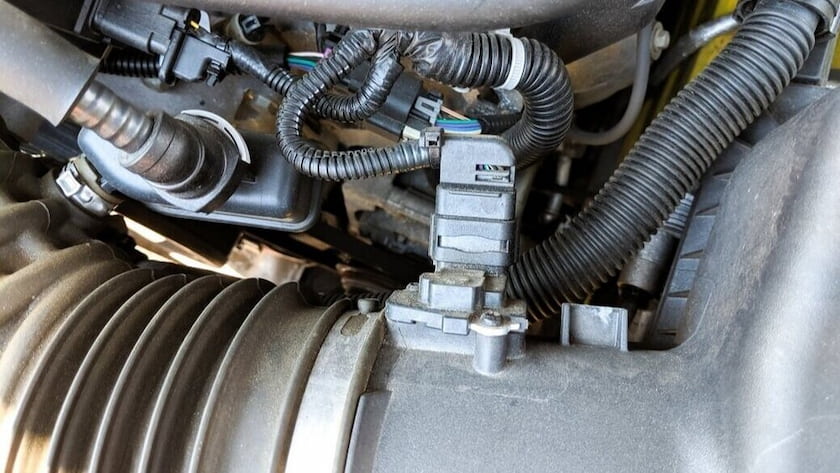

A mass air flow sensor (MAF) is a crucial engine part that measures the amount of air (or mass air flow) coming into the engine. It is installed in the intake piping, between the air intake and the inlet manifold. The real-time data it collects is relayed to the car’s ECU, which then can estimate the amount of corresponding fuel mass for efficient combustion. Without that information, the ECU can’t control the fuelling, and this has a literal knock-on effect on engine performance. So, the task mass air flow sensors perform may be simple, but vital for the proper operation of an EFI engine.

Since the density or mass of air coming into the engine depends on temperature, altitude, and whether forced induction is used, MAF sensors calculate that amount of air more precisely than a volumetric sensor. Combined with the data collected by the Oxygen sensor (which measures unburnt oxygen in the exhaust), the ECU gets a precise picture of the amount of air coming in, the efficiency of the combustion process, and whether changes to the air-fuel ratios are needed.

How does a MAF Work?

The most common type of MAF sensor is the so-called hot wire sensor. This has two sensing wires – one heating resistor, and an intake air temperature measurement resistor, along with a built-in air intake temperature sensor and an electrical control unit. The mass of air coming into the engine is measured by taking some of the intake air and redirecting it into the hot-wire measurement area. The measurement is then converted to the corresponding voltage in the control circuit and passed on to the ECU. During the whole process, the air intake temperature sensor measures how hot or cold the air is, so the ECU can judge how dense the air is and adjust the quantity of fuel sprayed by the fuel injectors.

Common Issues with MAF Sensors

Car parts manufacturers state that mass air flow sensors last the lifetime of the vehicle. However, due to the large quantity of air passing through them, sensors can fail due to dust, debris, oil and contamination not being picked up by air intake filters and by filters that are incorrectly installed. Sensors may fail early on (around 25000km in), and more often in cars with small displacement turbocharged engines. Driving with a faulty MAF sensor is possible, but a sensor that is damaged and not operational will cause a range of driving issues in the long run.

Some more common signs that the MAF has failed include:

• Check Engine Light – a faulty MAF sensor will get the check engine light excited. This though can mean a lot of things until the vehicle goes through a diagnostics scan and this pinpoints that the sensor Is at fault.

• Difficult Starts – If the engine won’t start, there’s the possibility that the MAF sensor isn’t reporting the air mass of incoming air, thus the air-fuel balance is off.

• Rough Idling or Stalling – Unusually high or low idling speed, or unstable idle is a sign of faulty air measurement readings. Stalling can occur very shortly after startup, either when the accelerator pedal is pressed or released.

• Issues While Driving – The engine hesitates during acceleration, there are loud knocking noises, and black smoke coming out of the exhaust. All implicate faults with the imbalanced air and fuel ratios, either a rich fuel mix (with more fuel than usual) or a lean fuel mix, with too much air. The engine running a rich mixture will substantially increase fuel use and point to a contaminated hot wire, whereas a lean mixture can mean a vacuum leak or contaminated sensor.

Suspect a Faulty MAF Sensor? Here’s What to Do

A diagnostics test with an OBDII scan will show most issues with failed MAF sensors. A simple cause may be a disconnected plug. More commonly though there will be damage to the platinum hot wire or the circuitry. If codes reappear after being reset, it’s time for a replacement part to be installed.

Remove the connector, unfasten the screws and lastly remove the sensor from the housing. If there is evident carbonisation and buildup of contaminants, the MAF sensor can be cleaned with a special cleaner. Otherwise, damage to the sensing probes, electronics, or housing calls for a new unit. Rerun the diagnostics scan to ensure that the fault has disappeared. Also, check the state of the air filter to ensure that it is clean.

Writing for the blog since 2012, Chris simply loves the idea of providing people with useful info on business, technology, vehicles, industry, sports and travel – all subjects of his interest. Even though he sounds like quite the butch, he’d watch a chick flick occasionally if it makes the wife happy, and he’s a fan of skincare routines though you’d never have him admit that unless you compliment his impeccable skin complexion.