Tech & Gadgets

Benefits of 3D Printing and the Importance of Quality 3D Printing Filament

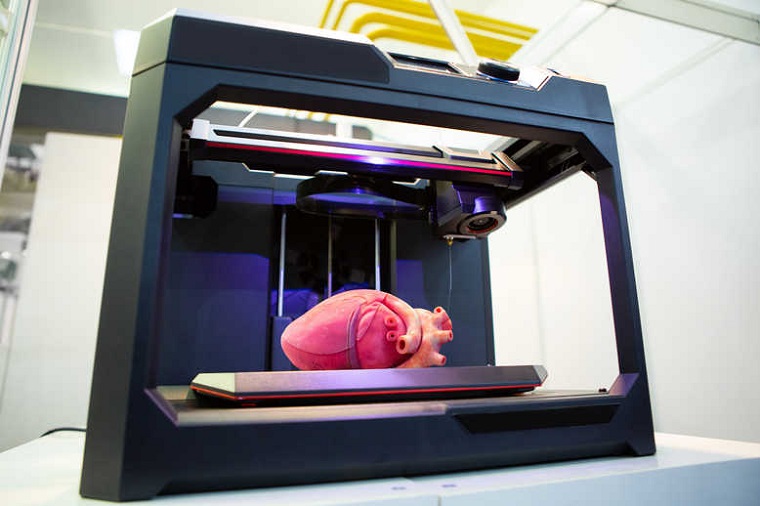

In the past couple of years, 3D printing has become more popular than ever as it is used in various industries around the world. The process involves the usage of 3D printers which create objects one layer at a time. This method offers much more advantages than manufacturing techniques, like CNC machining. In the near future, 3D printing is estimated to replace many traditional manufacturing techniques, and that’s for some very good reasons.

First, because it’s a fast process. This is one of the main advantages of 3D printing as it allows more parts to be produced in a shorter period of time. For example, a complex design can be printed for not more than a few hours, which is impossible with traditional manufacturing methods. The ability to produce functional end products at low to middle volumes offers a huge time-saving advantage. Another benefit is that 3D printing is a single step manufacturing process, and we all know that the production of most parts requires more steps.

Generally, the costs of manufacturing can be divided into three categories: labour cost, material cost and machine operation cost. Believe it or not, 3D printing beats traditional manufacturing in all three. In the process of 3D printing, two things are of great importance: a reliable printer and a high-quality 3D printer filament.

But what are the different 3D printer filaments? Currently, there are eight types of filaments on the market: engineering PLA, ABS filament, NYLON, PETG, carbon fibre filament, HIPS, PVA, Polypropylene and Flexible filament (TPU). And if you were wondering what is the best 3D printer filament, two of them stand out – PLA and ABS.

Characteristics of PLA

– PLA is made of renewable starches, like sugarcane and corn;

– It doesn’t emit noticeable amounts of ultra-fine particles and it’s biodegradable;

– It produces a barely noticeable smell;

– Depending on the colour and specifications, extrusion temperatures can vary between 190 and 230 Celsius degrees;

– PLA parts are more rigid than ABS parts;

– PLA parts have a slightly glossy finish;

– PLA is less prone to warping and much sticker than ABS;

– Regular PLA becomes malleable at around 60 Celsius degrees;

– PLA is a modern material and has a promising future in the 3D printing industry.

Characteristics of ABS

– ABS is petroleum-based filament;

– It’s cheaper than PLA;

– It produces ultra-fine particles so good ventilation is a must;

– It produces a “burnt plastic” smell;

– The extrusion temperature varies between 220 and 260 Celsius degrees;

– ABS parts are less brittle than PLA parts;

– ABS becomes malleable at around 100 Celisum degrees;

– ABS requires slightly less force to be extruded than PLA;

– Fun fact: the wold’s known LEGO blocks are made from injection-moulded ABS plastic.

3D filaments are the ink used by the printer to make products, which means their importance shouldn’t be underestimated if you want to achieve top-quality results. Now that we’ve listed some of the characteristics of PLA and ABS 3D printer filaments, let’s take a look at the important factors you need to consider the next time you set out to buy 3D printing filament.

3D filaments are the ink used by the printer to make products, which means their importance shouldn’t be underestimated if you want to achieve top-quality results. Now that we’ve listed some of the characteristics of PLA and ABS 3D printer filaments, let’s take a look at the important factors you need to consider the next time you set out to buy 3D printing filament.

- Diameter Tolerance – When using any type of 3D printer, the software that controls the printer calculates the extrusion volume based on the filament diameter, the extrusion speed and the diameter of your extruder nozzle. Or simply said, the printer controls the volume of plastic that is pushed out of the nozzle. Because of this, if you have a filament with an irregular diameter, the software won’t adjust the extrusion length and instead, it will keep on printing. The final result would be an inconsistent extrusion. Ideally, the filament should maintain a consistent diameter across the entire spool but in real life, there is always a tolerance. The tolerance of a filament diameter describes the variations that are present in the filament you use. When looking at filament tolerance, a gold standard in the industry is 0.05mm.

- Filament Roundness – When the filament comes in contact with the extruder wheel, it suffers some compression. This process reduces the roundness of the filament, but since it still stays consistent across the entire spool – it may not really affect the final results and print quality. But this doesn’t make filament roundness across the entire spool less important. Instead, if the filament suddenly loses its round shape and becomes oval, it can lead to extrude failure which will further decrease or increase the filament diameter.

- Spool Dimensions – The form and size of the spool are one of the most debated topics in the 3D world. There are several key dimensions in any spool: the mounting diameter, the flange diameter, the width od the spool and the inner coil diameter. All of them are important as they can affect the mounting compatibility of the filament since most 3D printer manufacturers attempt to persuade consumers into buying only their filaments. To maximize extruder strain and maintain a constant setup, look for a spool with an inner coil diameter that’s greater than 80mm.

- Filament storage – If you are spending money on a quality filament for high-quality results, filament storage is important. The biggest issue with most types of plastic is that, over a certain period of time, they absorb moisture which creates bubbles in the filament. These small bubbles dramatically reduce the quality of the prints. Generally, there are two main strategies for storing filaments. One is to store them in a sealed ziplock bag. On the other hand, for bulk storage, one of the ways is to use plastic bins and a bucket of uncooked rice that works as a natural desiccant. Both of these are effective and inexpensive solutions.

Writing for the blog since 2012, Chris simply loves the idea of providing people with useful info on business, technology, vehicles, industry, sports and travel – all subjects of his interest. Even though he sounds like quite the butch, he’d watch a chick flick occasionally if it makes the wife happy, and he’s a fan of skincare routines though you’d never have him admit that unless you compliment his impeccable skin complexion.