Tech & Gadgets

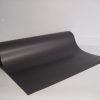

The 3 Benefits of Professional 3D Printers & Tips on Finding the Right One

3D printing is one of the greatest inventions in the world of today. It has made manufacturing custom parts easier, which has led to many people who use desktop printers in their houses and businesses to implement professional ones in their line of work. While the former ones are simple to use and easy to find, the latter ones seem to be quite the opposite as the needs of businesses don’t often match the capabilities of professional 3D printers. What this means is that you should know what you actually need before you start looking for the ideal model for you. Before we get to that part, let’s first take a look at the benefits that professional 3D printers offer.

Benefits

Professional (commercial) printers are made in a way so that there is no warping whatsoever, and unlike a hobby printer, the parts always come out true. The consistency in print quality of 3D professional printers is unmatched as they can print a part that is ten thousand of an inch to the STL file over and over again.

Most professional printers do not require to be monitored while printing, and unlike hobbyist machines, they can run all night on their own. This means that you can easily multitask and not run into problems such as a decrease in print quality.

There are a lot of printers, both hobbyist and commercial ones, that make use of support materials which are meant to act as a scaffolding, However, 3D professional printers do not require any sanding after the part has been printed in order to get rid of the divots left by the support material.

The material that’s used for the process of printing plays an important part in the outcome as it determines the quality of the final product. Plastic and nylon materials together with PLA (polylactic plastic) and ABS ( acrylonitrile butadiene styrene) are the most popular nowadays since they are very cost-effective. But if you want a more durable and stronger part, materials like carbon fibre and Kevlar are the best options, while there are also printers that use bronze, gold, steel and even ceramic.

Resolution

The resolution of a printer is what makes the part smoother and rich in detail, with the range being from 16 – 200 microns. The higher the micron count, the lower the printing quality. While a regular printer may have a resolution between 100 and 150 microns, more high-end ones have it between 75 and 60 microns which is about the same thickness of a human hair. If you want the finest detail quality, go with SLA (stereolithography) printers as there are some that can print down to 16 microns – a size smaller than a grain of pollen.

With the performance and speed of a 3D professional printer, you’ll need to have in mind which ability you want to dominate. For, example while the SLA printer is able to print 15mm of a block per second, an extruder one can reach up to a 100 or maybe a 150mm per second. A faster printer will be able to print multiple different pieces faster, slower printers (which are usually bigger) will allow you to print multiple smaller pieces at once. It all comes down to what you’ll be printing most of the time.

Software

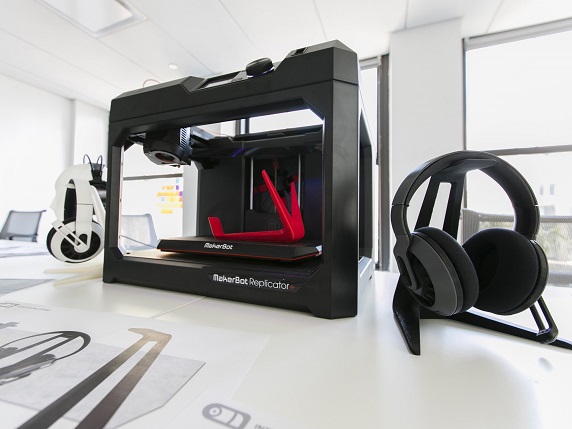

The software that comes with the 3D professional printers also plays a role in their efficiency and no matter what you are going to be printing, you’ll need to send the commands through the CAD (Computer-Aided Design) program. Although almost every printer out there comes with one, you can still use alternatives like Slicr, Octoprint, Materialise and many more – some of them are even incorporated in the cloud. These programs make sure you don’t mess up the support material as they render the honeycomb scaffolding themselves and can run several printers at once.

Other Features

There are other features and parts of professional 3D printers which may not seem like they matter that much but they do – it’s the details that make a world of difference. First, what you need to look for is a built-in camera so that you can take a look at what’s going on without having to leave your other projects unattended.

Next, we have the stands which not only offer a sturdy surface to place the printer on, but they also come with small cabinets so you can store the most used tools in the most accessible place. While a printer with a touch-screen control panel may not be your priority, it is certainly a convenient feature that will allow you to access the printer’s settings more easily.

The build plate is the surface inside the printer where all the work happens and because of that, you need to have several build plates so you continue with the printing process by just replacing the used up plate with a new one. While some printers will have the printing material all set in a package, others will require you to put it in a container inside the printer.

You can choose the colour of the materials you use – some can glow in the dark or have a neon shade. Keep in mind that in order to print with different types of materials and different coloured-ones, you need to have more than one extruder – this is the printing nozzle. Most threads on the internet will tell you to plug in the printer using a USB cable, but if you want to have a faster file transfer, a network cable is what you need.

Writing for the blog since 2012, Chris simply loves the idea of providing people with useful info on business, technology, vehicles, industry, sports and travel – all subjects of his interest. Even though he sounds like quite the butch, he’d watch a chick flick occasionally if it makes the wife happy, and he’s a fan of skincare routines though you’d never have him admit that unless you compliment his impeccable skin complexion.