Automotive

Unleashing the Roar: Exploring the World of Performance Exhausts

In the pursuit of automotive performance perfection, enthusiasts often turn their attention to the exhaust system, recognizing its pivotal role in unlocking the hidden potential of their vehicles. A high-performance exhaust isn’t just about generating an aggressive growl; it’s a strategic combination of advanced components and cutting-edge technologies designed to enhance engine efficiency and power output.

Having said that, let’s delve into the intricacies of performance exhausts, and explore the various components, manufacturing technologies, and materials that contribute to their unmatched prowess. From the benefits of lightweight materials like aluminised steel, titanium, and carbon to the significance of mandrel bending in optimizing airflow, we’ll uncover the secrets behind creating exhaust systems that redefine automotive exhilaration.

Components of a Performance Exhaust System

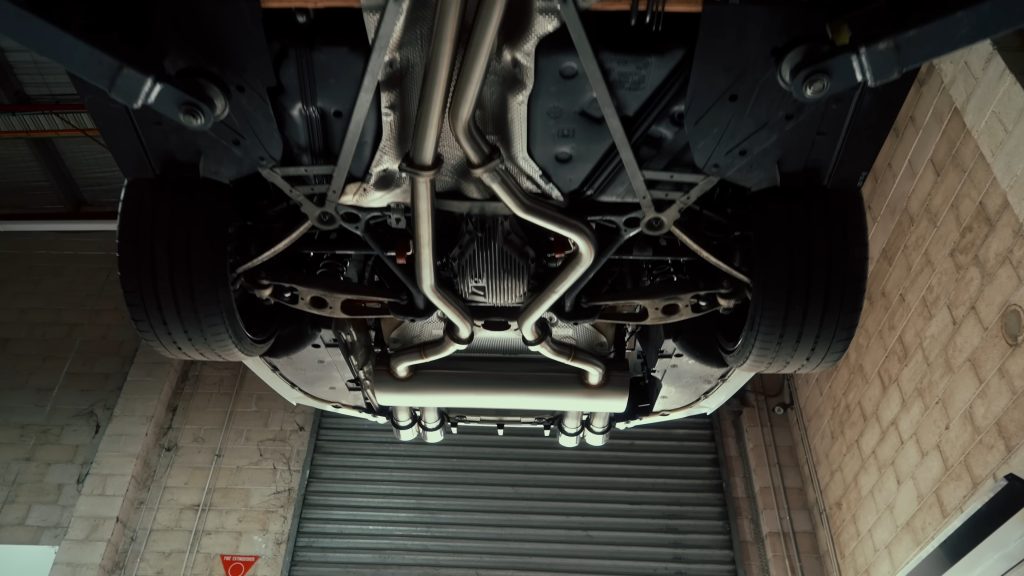

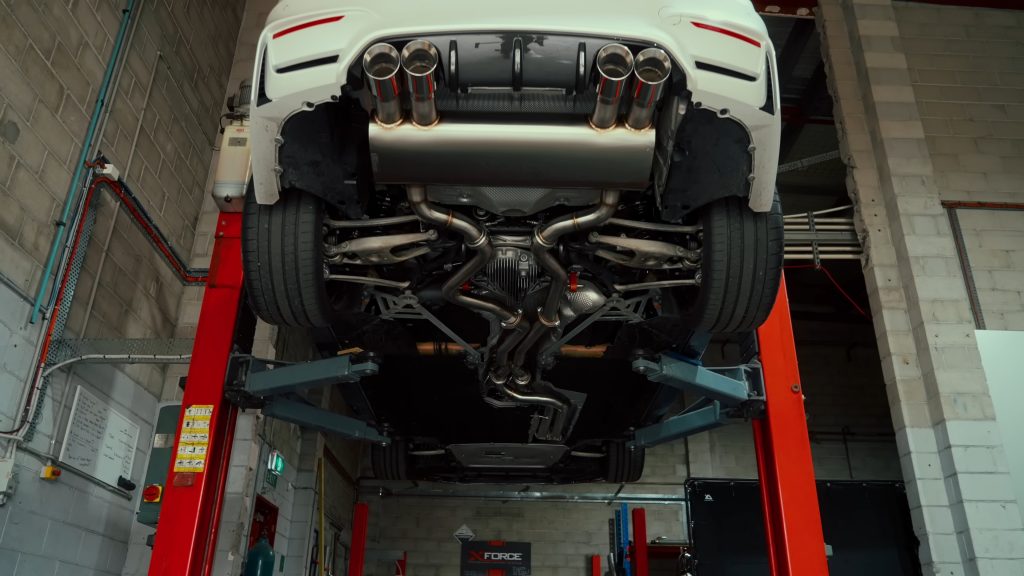

Headers/Exhaust Manifolds

Performance headers or exhaust manifolds are engineered to efficiently expel exhaust gases from the engine’s cylinders. Unlike stock versions, performance headers are designed with equal-length tubes to enhance exhaust gas scavenging, optimizing cylinder evacuation for improved efficiency.

Catalytic Converters

High-performance catalytic converters are designed to reduce exhaust gas restrictions, promoting smoother flow. Some performance exhaust systems feature high-flow catalytic converters or even catalytic converter deletes for track-focused applications, where emissions regulations permit.

Mid-Pipes

The mid-pipe connects the headers to the mufflers, and its design plays a crucial role in the exhaust flow. Performance mid-pipes often incorporate resonators or crossover pipes to balance pressure between cylinders and enhance exhaust scavenging, contributing to power gains.

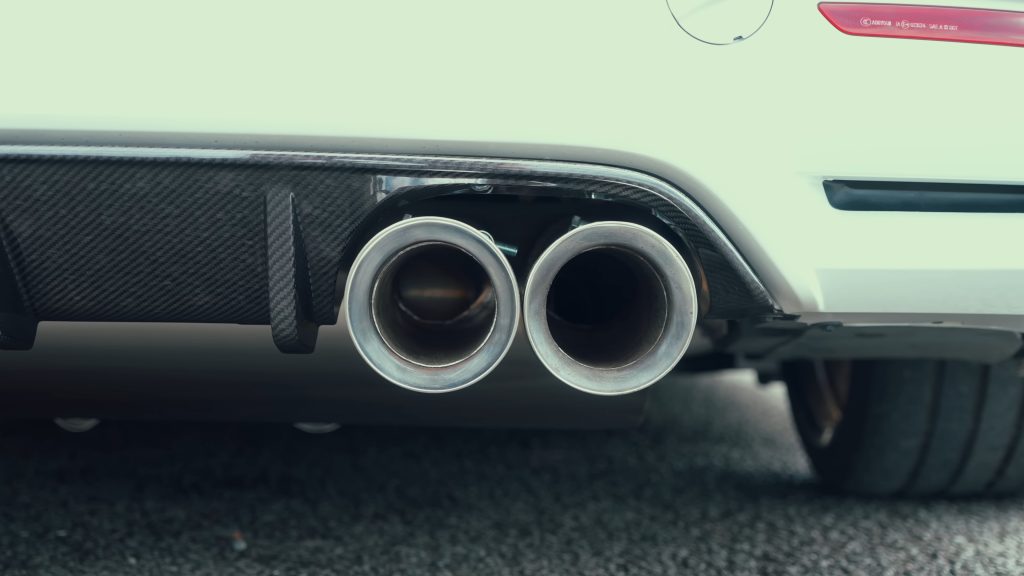

Mufflers

Performance mufflers are engineered to reduce backpressure and enhance exhaust flow without compromising the desired exhaust note. They often feature straight-through designs, improved internal baffling, or even electronic valves for adjustable sound levels.

Materials Used in Performance Exhausts

Aluminised Steel

Aluminised steel is a cost-effective material with excellent corrosion resistance. Performance exhausts crafted from aluminised steel offer durability and longevity while providing weight savings compared to traditional steel systems.

Titanium

Titanium exhausts are renowned for their exceptional strength-to-weight ratio. These systems significantly reduce overall weight, enhancing vehicle performance. Titanium’s resistance to corrosion makes it a preferred choice for high-end, performance-oriented applications.

Carbon Fiber

Carbon fiber is a lightweight, high-strength material used in select performance exhaust components like tips or heat shields. While not commonly used for entire exhaust systems, its application contributes to overall weight reduction and adds a touch of aesthetic appeal.

Benefits of Lightweight Materials

Improved Power-to-Weight Ratio

Lightweight materials contribute to a favorable power-to-weight ratio, enhancing acceleration and overall vehicle performance. Reduced exhaust system weight means less mass for the engine to work against.

Enhanced Handling and Agility

Weight reduction in the exhaust system has a positive impact on a vehicle’s handling dynamics. By minimizing the unsprung weight, especially towards the rear, the car becomes more responsive and agile.

Increased Fuel Efficiency

A lighter exhaust system reduces the vehicle’s overall mass, resulting in improved fuel efficiency. The engine doesn’t have to work as hard to propel the vehicle, leading to better miles per gallon.

Mandrel Bending Technique

The mandrel bending technique is a crucial aspect of crafting high-performance exhaust systems. Unlike crush bending, which can deform the tubing and hinder exhaust flow, mandrel bending maintains a consistent inside diameter throughout the curves. This ensures that the exhaust gases can flow smoothly, reducing turbulence and backpressure.

Benefits of Mandrel Bending

Optimized Airflow

Mandrel bending allows for smooth, uninterrupted airflow within the exhaust tubing. This promotes efficient evacuation of exhaust gases, reducing backpressure and enhancing engine performance.

Consistent Inside Diameter

The use of a mandrel ensures that the inside diameter of the exhaust tubing remains uniform, preventing any constriction or deformation. This consistency is vital for maintaining optimal exhaust flow.

Minimized Turbulence

By preserving a constant inside diameter, mandrel bending minimizes turbulence in the exhaust system. This reduction in turbulence leads to improved scavenging, helping the engine breathe more efficiently.

Performance Gains

Mandrel-bent exhaust systems contribute to performance gains by reducing restrictions in the exhaust flow. The engine can expel exhaust gases more freely, resulting in increased horsepower and torque.

Additional Considerations for Performance Exhausts

Tuned Exhaust Lengths

Some performance exhaust systems are engineered with tuned lengths for specific RPM ranges. These systems optimize exhaust pulses, enhancing scavenging and power delivery across the RPM spectrum.

Exhaust Heat Management

Performance exhaust systems often incorporate advanced heat management technologies to mitigate excessive temperatures. This includes ceramic coatings on headers or the use of thermal wraps to prevent heat soaking in surrounding components.

Sound Engineering

Achieving the desired exhaust note is an integral part of performance exhaust design. Manufacturers employ advanced sound engineering techniques, including Helmholtz resonators or adjustable baffles, to tailor the exhaust tone while maintaining optimal performance.

Conclusion

In the realm of automotive performance, a well-designed and meticulously crafted exhaust system can be the key to unlocking a vehicle’s true potential. From the choice of materials like aluminised steel, titanium, and carbon fiber to the implementation of mandrel bending techniques for optimized airflow, every component plays a crucial role.

Enthusiasts seeking an exhilarating driving experience can leverage the advancements in performance exhaust technology to not only enhance engine performance but also achieve a distinctive and satisfying exhaust note. As automotive engineering continues to push boundaries, the evolution of performance exhaust systems remains at the forefront, offering enthusiasts a symphony of power, precision, and passion.

Writing for the blog since 2012, Chris simply loves the idea of providing people with useful info on business, technology, vehicles, industry, sports and travel – all subjects of his interest. Even though he sounds like quite the butch, he’d watch a chick flick occasionally if it makes the wife happy, and he’s a fan of skincare routines though you’d never have him admit that unless you compliment his impeccable skin complexion.